Kunshan Xingbao Plastic

Installation Details

| Location: | Kunshan Xingbao Plastic www.xinbaoplastic.com |

| Model: | |

| Installed by: | Xinriyuan |

Xingbao Plastic

It covers 40,000 square meters and has about 400 employees. The major business lines include plastic injection, product assembling, painting, non-conductive vacuum metallization and mold manufacturing, and its wide ranges of products in the fields of electronics, home appliances, auto parts, medicine, and gardening are exported throughout the world.

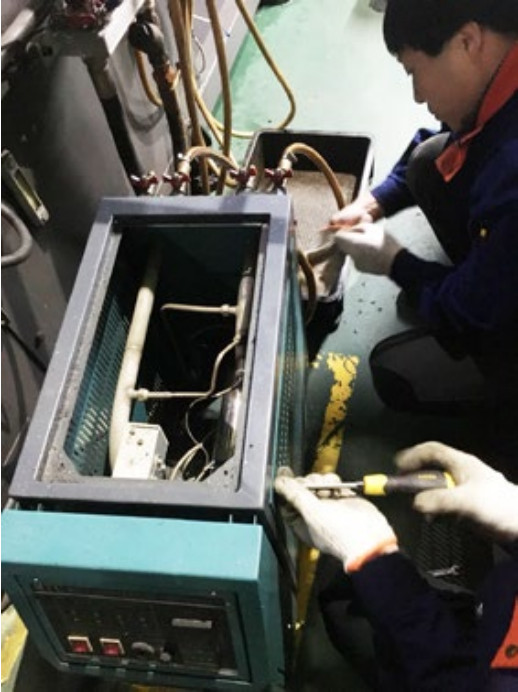

Untreated heat exchanger for 3 years and after installing Vulcan for 1.5 years, the scale is gone without extra cleaning.

The scaling problems and the result

The injection molding machine had been scaled badly for years, so it was always difficult to clean the pipe, especially the heat exchanger of the mold temperature controller. The traditional cleaning way is to use a chemical, but it is costly and difficult, and it also harms the heat exchangers and pipelines.

After Vulcan S150 and S250 were installed, the clients are fully satisfied with their performance because they solved the scaling and iron filing problems on injection molding machines.

One and a half years after Vulcan was installed, we opened the mold temperature controller and checked the heat exchanger.